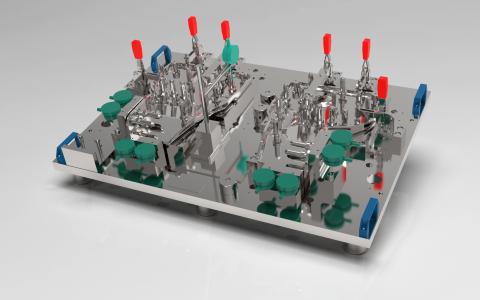

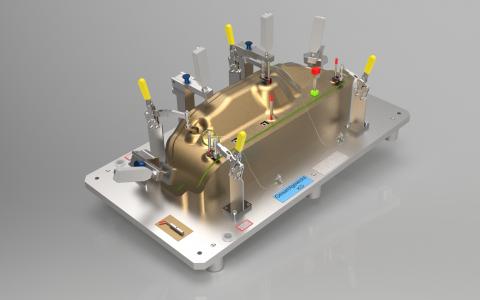

- in the design process using FMEA techniques and Poka-yoke techniques. Fast prototyping helps to predict potential problems.

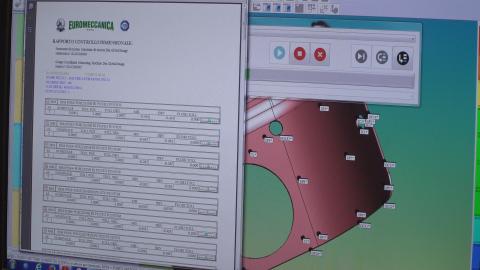

- in the production control with statistical methods in the digital production management to guarantee high level of service

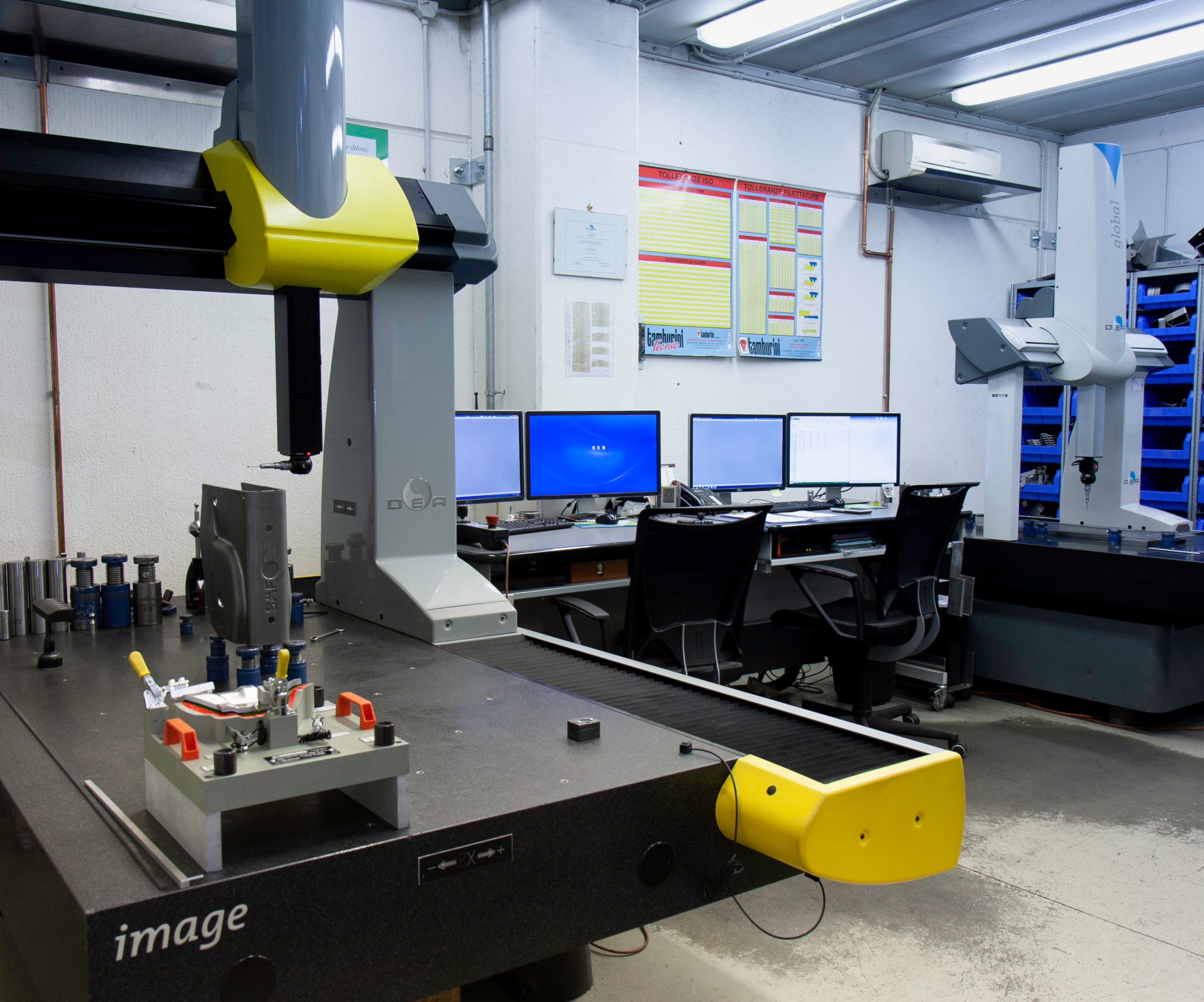

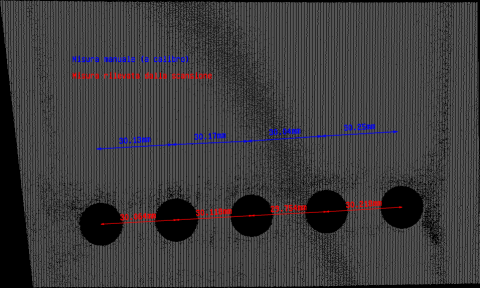

- in the 100% measurement or sampling of finished parts with contact measurement instruments or precision visioning with laser scanning.

"Zero PPM" objective

We use in-line verification procedures that can guarantee and verify the quality of the product even in the presence of complex processes. We design the templates in order to guarantee a quick and accurate control. Modern vision technologies allow us to verify some characteristics of the products on 100% of the pieces.

Certifications

We know the importance of certifications according to European and international standards, but we implement them in order to be compliant with the audit of customers who have specific needs and which can not be standardized in a single certification.

English

English Italian

Italian