Our equipment and facilities

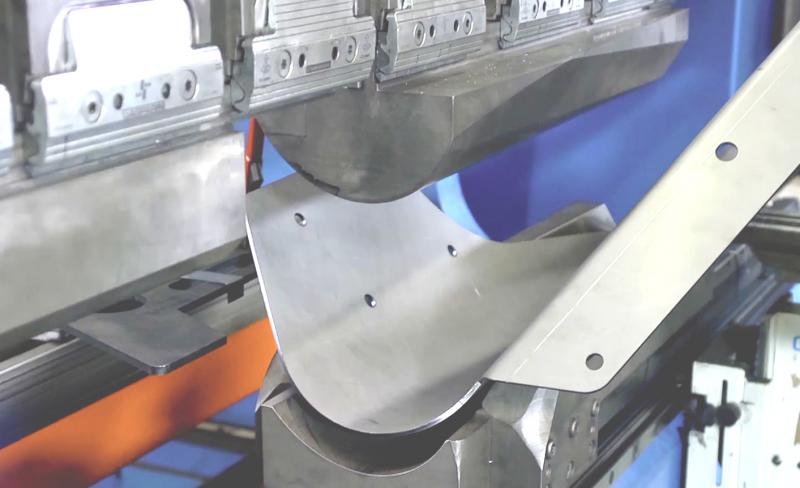

The stamping department has a complete range of mechanical and hydraulic presses, up to 2000 tons. Each press has a back-up solution inside the same department, to always guarantee the customer a continuity of supplies. The plant is air-conditioned to guarantee the performance of our mechanical and electronic equipment and optimal comfort for the operators. We use the self-produced energy with the photovoltaic system and invest on the efficiency of the plants.

We process various materials from tape or sheets: steel, stainless steel, aluminum and high-strength steel from 0.2 mm up to 15 mm.

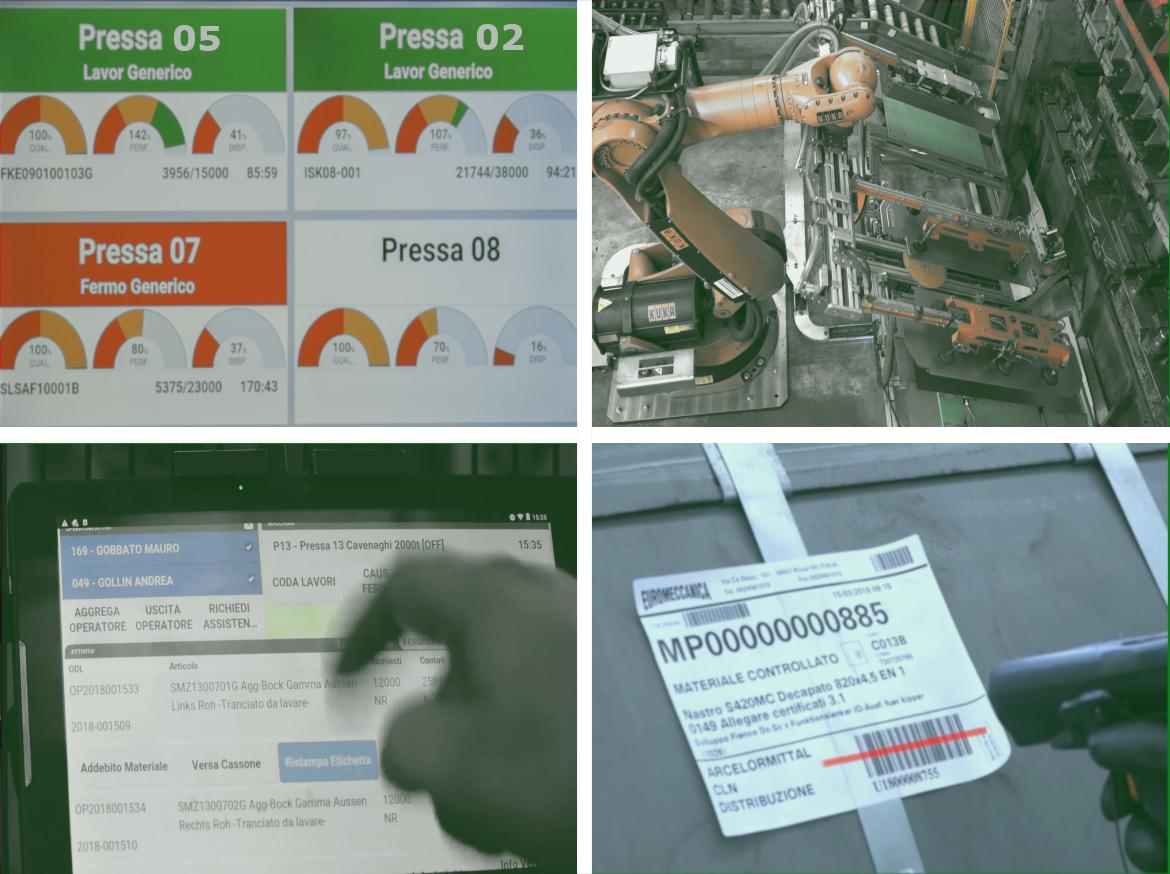

Production management

Thanks to its production system, Euromeccanica meets the most stringent standards in the automotive, energy and household appliances sectors. Traceability, automation and management of digital production always allow us to have full control of our factory.

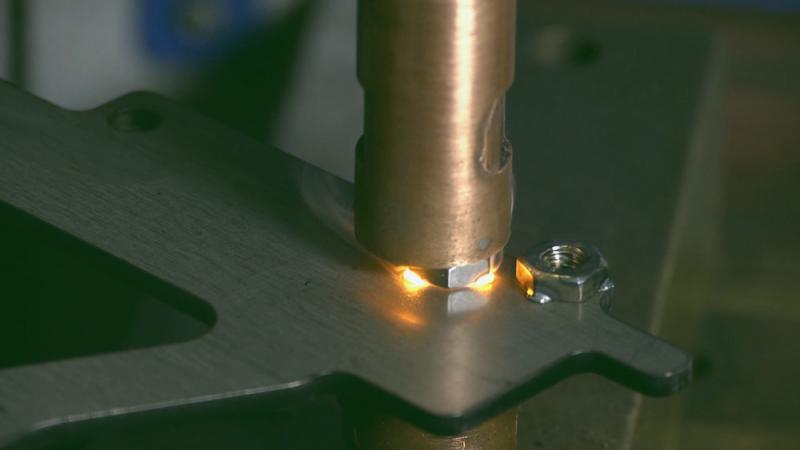

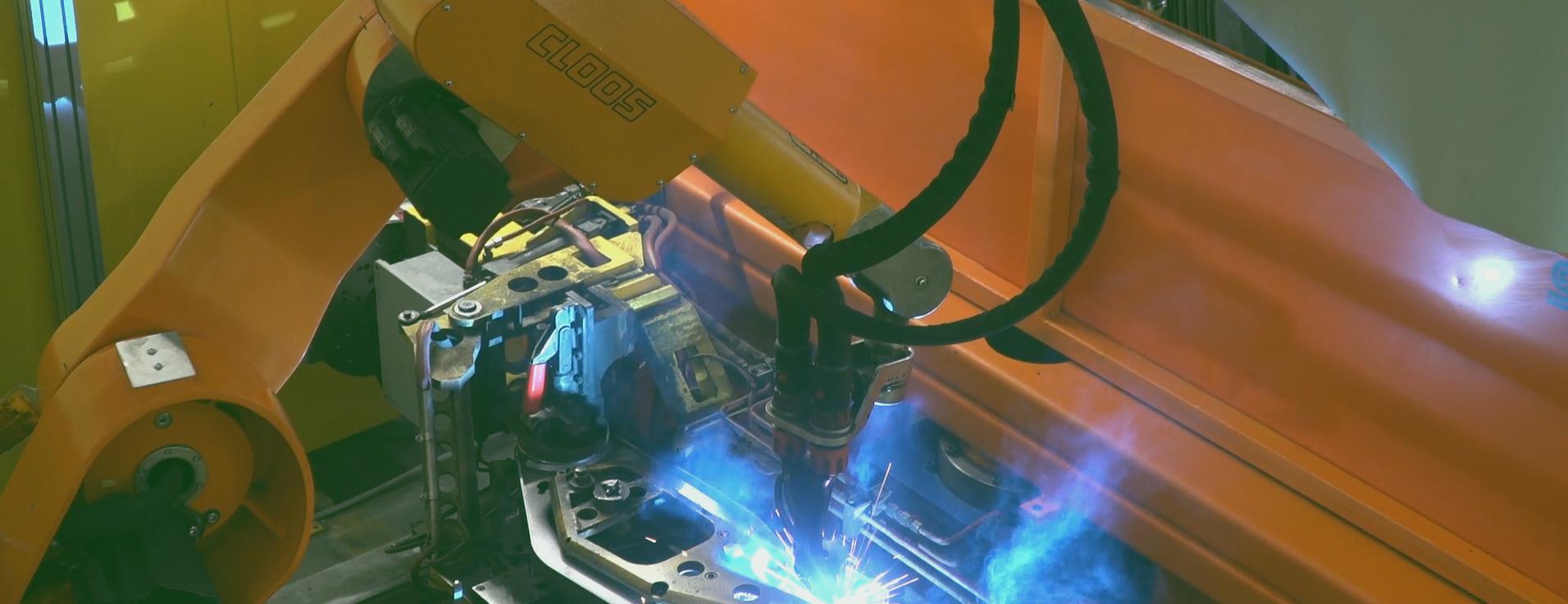

Welding and other services.

Euromeccanica has developed a years-long experience in steel products welding. It has all the process and operators certifications to guarantee quality and security to customers in the automotive sector, even on thicknesses up to 8 mm. We continuously invest in equipment that guarantees consistency and efficiency in the execution of the work.

We also manage all the processes that the customer needs thanks to the departments within the Euromeccanica Group and to the proven suppliers for whom Euromeccanca is a point of reference in the territory.

English

English Italian

Italian